Sisal is a renewable resource par excellence and can form part of the overall solution to climate

change. Measured over its life-cycle

Sisal absorbs more carbon dioxide than it produces. During processing,

it generates mainly organic wastes and leaf residues that can be used to generate

bioenergy, produce animal feed, fertiliser and ecological housing materialand,

at the end of its life cycle, sisal is 100 percent biodegradable.

By contrast synthetically produced fibres do not possess any of these traits.

FEATURES

- High resistance when in contact with salt water

- High resistance to UV radiation

- Low elongation compared to synthetic fibers

- Stable and solid knotting

|

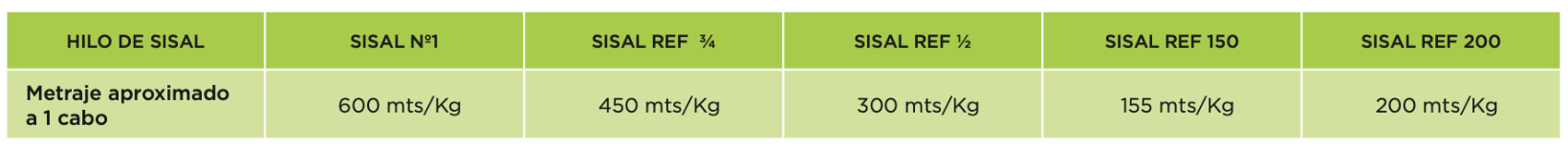

SISAL TWINE |

SISAL Nº1 | SISAL REF 3/4 | SISAL REF 1/2 | SISAL REF 150 | SISAL REF 200 |

|---|---|---|---|---|---|

|

1 strand approximate runnage |

600 mts/Kg | 450 mts/Kgs | 300 mts/Kgs | 155 mts/Kgs | 200 mts/Kgs |

An approximate variation margin of at least 5% should be considered in the data provided regarding the density of the product. The above mentioned references can be manufactured in formats from 1 to 9 strands depending on the thickness of the thread.

The packaging can vary from 700 gr / unit reels to industrial size reels depending on the thickness of the product.

|

SISAL ROPES |

4mm | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm | 22mm | 24mm | 26mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Approximate weight in 4 strands & 100mt coils |

1,45 Kgs | 2,75 Kgs | 4,75 kgs | 6,50 kgs | 9,50 Kgs | 12,50 Kgs | 16,50 Kgs | 21,50 kgs | 25,75 Kgs | 31,50 Kgs | 37,25 Kgs | 42, 50 Kgs |

An approximate variation margin of at least 5% should be considered in the data provided regarding the density and weight of the product.

Debe considerarse un margen de variación aproximado de al menos un 5% en los datos aportados referentes a la densidad del producto. Las referencias arriba mencionadas pueden fabricarse en formatos desde 1 a 9 cabos dependiendo del grosor del hilo.

El envase puede variar desde bobinas de 700 gr/ud hasta bobinas de tamaño industrial dependiendo del grosor del producto.

Debe considerarse un margen de variación aproximado de al menos un 5% en los datos aportados referentes a la densidad y peso del producto.